ACF Awarded 9th Patent for Single-Phase, Fiber-Reinforced Ceramic Matrix Composites

October 6, 2020

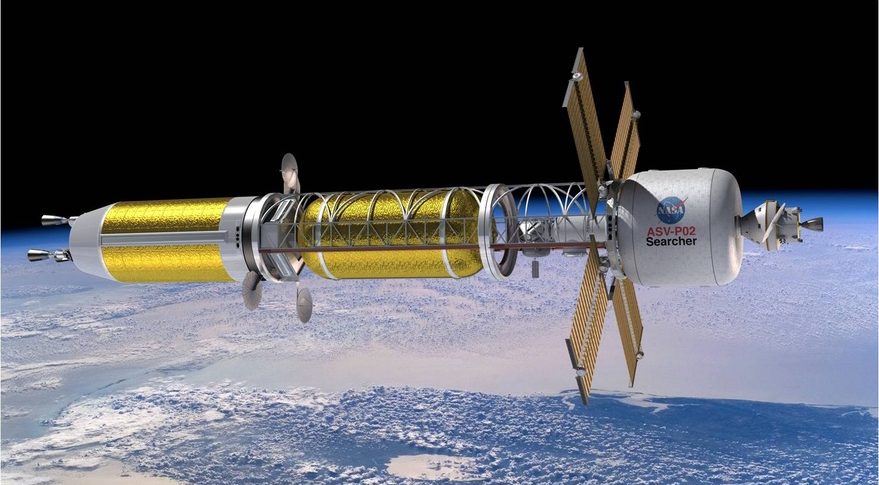

ACF Works Again With The John Hopkins University Applied Physics Lab On A Heat Exchanger Made Of Converted Fiber Braided Tubes For Nuclear Thermal Propulsion In Space

January 15, 2021

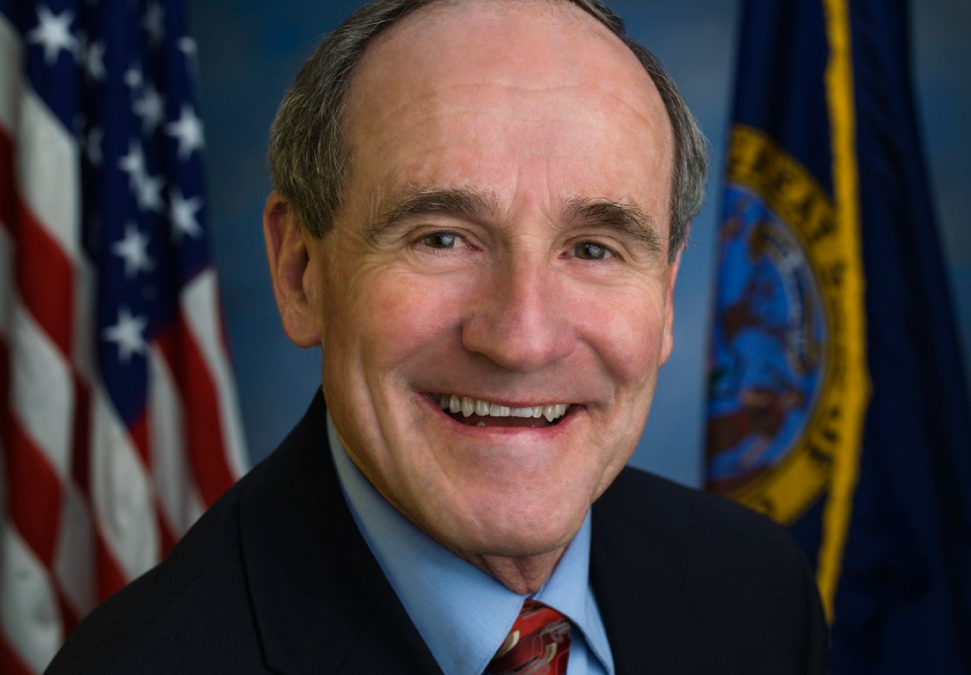

ACF named Small Business of the Month by U.S. Senator Jim Risch

In February, 2016 ACF received the "Excellence in Business" Award for 2016 by the Idaho Small Business Development Center. The award was given during the Small Business Development Center's 30 Anniversary luncheon held in Boise, Idaho. State Senator Dean Mortimer, R-Idaho Falls, presented the Region VI award during the luncheon. Ken Koller, ACF's President/COO accepted the award for the company.

Related posts

July 13, 2021

January 15, 2021