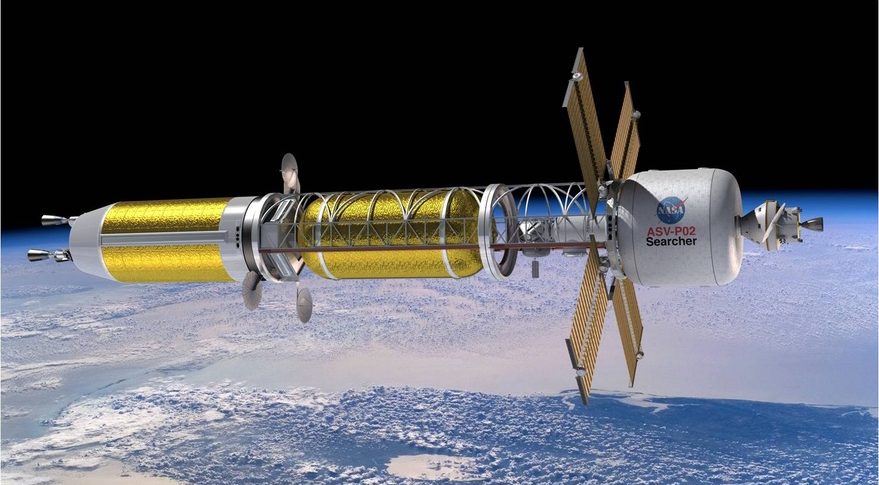

ACF Works Again With The John Hopkins University Applied Physics Lab On A Heat Exchanger Made Of Converted Fiber Braided Tubes For Nuclear Thermal Propulsion In Space

January 15, 2021NASA Interstellar Probe Study

This article was published on "CompositesWorld," July 13th, 2021. The article details the results of a seven-month project that detailed the ability to withstand up to 3,500°C and it showed promising initial results.

Related posts

January 15, 2021