ACF Awarded Contract from DOE for 1704° C (3100°F) Turbine Engine Materials for Stationary Power

August 19, 2020

ACF Relocates to Expanded Facility

October 1, 2020July 1, 2020

PRESS RELEASE

ACF Announces Small Business Innovation Research Award

National Aeronautics and Space Administration

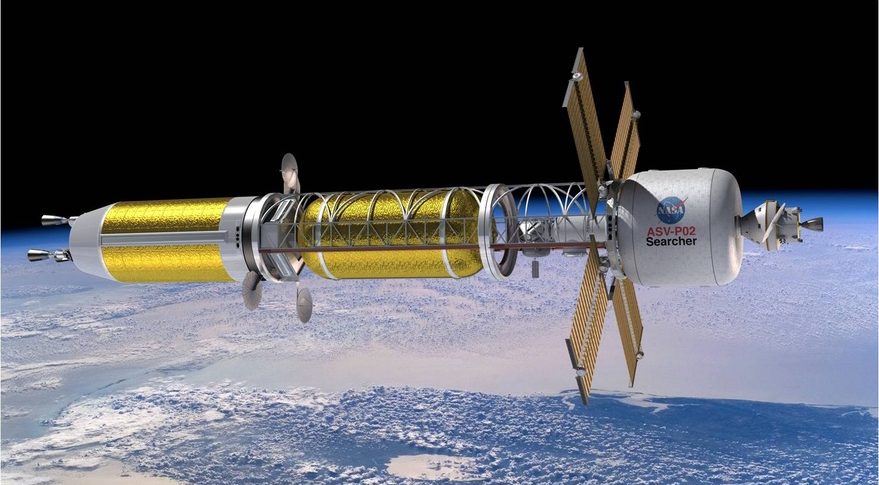

Idaho Falls, Idaho - Advanced Ceramic Fibers, LLC (ACF) a small, advanced materials technology-based business, has been recommended for a Phase I Small Business Innovation Research (SBIR) award from the National Aeronautics and Space Administration (NASA). As governments and commercial entities compete for opportunities to travel to Mars and throughout deep space, the need for more efficient engines, reduced launch weight and increased payload capacities are constantly being developed. NASA is re-engaging its interest in Nuclear Thermal Propulsion because of its promise to double the efficiencies of competing engine types and fuels including higher energy density, greater thrust, reduced weight and increased velocities.

Utilizing novel fibers, matrices and fabrication methods, ACF has proposed to develop and demonstrate a new type of ceramic matrix composite (CMC) specifically designed to meet the specifications and performance properties required for long-term use in Nuclear Thermal Propulsion (NTP) engines. ACF’s unique approach will exhibit revolutionary refractory capabilities, reduced hydrogen permeability, radiation tolerance, low creep, high thermal and mechanical stability, retention of fission products and improved manufacturability. The potential advantages of Nuclear Thermal Propulsion can now be realized through the development of novel materials and advanced manufacturing processes by a U.S. supplier.

NTP engines can safely and efficiently produce electricity, heat and propulsion. NASA applications include but are not limited to: solar system exploration, rocket engines for Mars and deep-space vehicles; interstellar transportation, power support for the International Space Station (ISS), and near Earth object (NEO) missions; auxiliary and on-board electrical power generation; power for interplanetary research stations, in situ resource utilization (which includes mining operations), life support and communication systems.

ACF’s project entitled: “Low-Risk Approach to High-Payoff Ultra-High Temperature Ceramic Matrix Composites”, is anticipated to begin October 1, 2020, with a completion date of March 28, 2021. ACF has received a letter of support from Armstrong Material Solutions, LLC and their affiliate company EEMS, LLC, due to their interest in innovative pre-ceramic polymer concepts that could significantly improve the state-of-the-art in ceramic matrix composites.

ACF’s facilities are located in the Idaho Innovation Center (IIC) on 2300 N. Yellowstone Hwy, Idaho Falls, Idaho. Facilities available to ACF include the fiber conversion process production system center and associated business offices. ACF’s office phone number is 208-522-6008 and website address is www.acfibers.com.